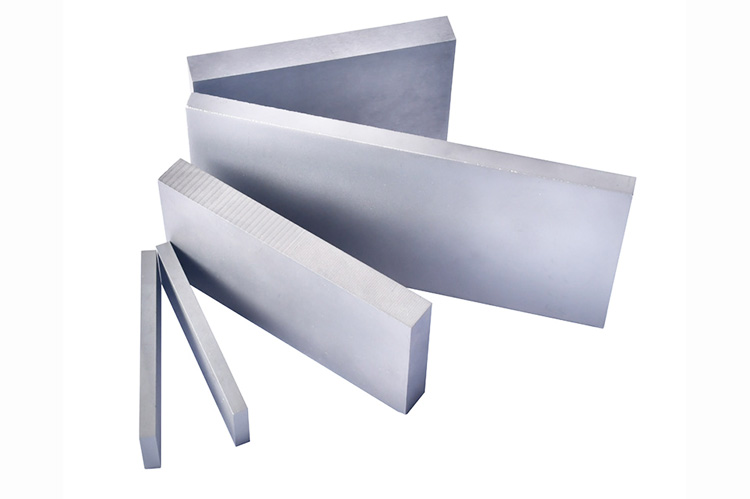

Custom of Cemented Carbide Wear Plates Components

Custom cemented carbide wear plates with tungsten carbide & cobalt. High-performance wear-resistant components for mining, steel industries. Factory direct.

- Info

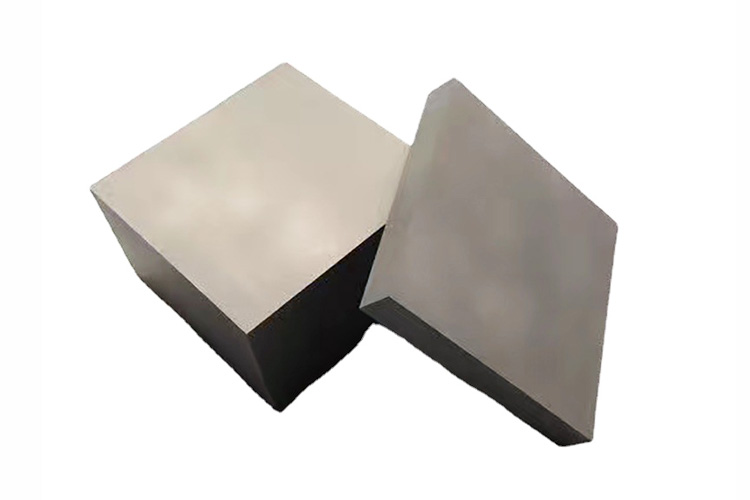

Tungsten Carbide Wear Plates Components

Tungsten carbide wear plates are high-performance wear-resistant sheets made with tungsten carbide as the primary wear phase and cobalt, nickel, or similar metals as binders using vacuum sintering processes. They have a dense microstructure and uniform hardness distribution, and the wear layer and substrate achieve metallurgical bonding to prevent delamination during use.

Core Features

The product’s core features include extremely high wear resistance, excellent impact resistance, and good corrosion resistance, allowing them to withstand severe abrasion and impact from bulk materials.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Primary Applications

They are primarily used for wear protection in cement plants, power plants, steel mills, and mining industries, commonly appearing as chute liners, fan blades, mixer blades, and conveyor liners—areas prone to heavy wear.

Advantages Over Steel Plates

Compared with traditional wear steel plates, tungsten carbide wear plates offer significantly better wear performance, lighter weight, and easier installation, substantially reducing equipment maintenance.

Full-Service Customization

We provide full-service customization and can produce wear plates in different sizes, thicknesses, and hardnesses based on customers’ equipment wear patterns and operating conditions.

| Product Attributes | |

| Name: Cemented Carbide Wear Plates, | Grade: K20, YG6, YW1, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.003 mm. |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.