Sintered Cemented Carbide Parts | Custom Manufacturer

Sintered tungsten carbide parts use refined cemented carbide materials and precision metallurgy for stable performance, offering custom OEM solutions and fast delivery.

- Info

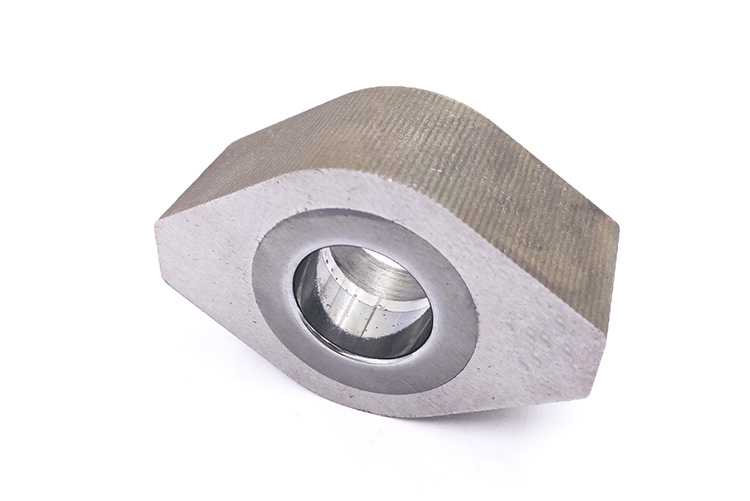

Sintered Tungsten Carbide Parts

Sintered tungsten carbide parts are made from tungsten carbide powders mixed with cobalt, nickel, or other metallic binders through precise formulation, pressing, and high-temperature sintering processes. This powder metallurgy technique ensures uniform internal structure and high density, which is key to combining complex shapes with high performance.

Key Properties

Parts produced by this method have extremely high hardness, excellent wear resistance, and high compressive strength; the metallurgical bonds formed during sintering provide good red hardness and chemical stability.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Primary Uses

They are mainly used in cutting tools, molds, wear parts, and critical components in automated equipment, especially where high precision and long life are required.

Advantages of Sintering

Compared with conventionally machined parts, sintered tungsten carbide components can achieve near-net shape forming, reducing material waste and enabling complex geometries with better performance consistency and typically longer service life.

Full-Process Customization

We offer full-process customization—from powder formulation to sintering parameters—and can adjust material composition, density, and sintering settings to meet customer requirements.

| Product Attributes | |

| Name: Sintered Cemented Carbide Parts, | Grade: K10, YG6A, YW1, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.003 mm. |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.