Custom High-Hardness Rolls | Tungsten Carbide Roll Manufacturer

As a professional tungsten carbide roll manufacturer, we are committed to providing our customers with high-hardness, high-wear-resistance roll solutions. Our products are not standard items, but are customized to your […]

- Info

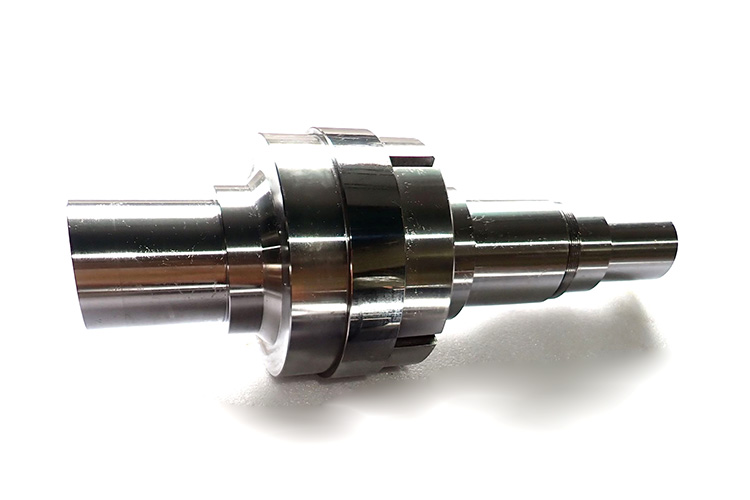

As a professional tungsten carbide roll manufacturer, we are committed to providing our customers with high-hardness, high-wear-resistance roll solutions. Our products are not standard items, but are customized to your specific working conditions. We provide custom manufacturing based on your drawings or design roll product drawings according to your requirements, ensuring perfect performance and demand matching.

Core Advantages of Our Tungsten Carbide Rolls

Our tungsten carbide rolls feature extremely high hardness (HRA ≥ 88) and excellent wear resistance. We can select different contents and brands of tungsten carbide according to customer requirements. The products utilize ultra-fine particle tungsten carbide (WC) and cobalt-based binder composite sintering technology, ensuring the rolls maintain structural stability under high-pressure, high-temperature working conditions. Service life is significantly improved, substantially reducing downtime for roll changes and greatly enhancing production efficiency. Additionally, tungsten carbide material exhibits excellent compressive strength and corrosion resistance, maintaining stable dimensional accuracy and surface finish even in harsh rolling environments with high speed, high pressure, and high temperature.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Superior Performance and Longevity

High-hardness, high-wear-resistance rolls have a service life 2-3 times that of traditional high-chromium steel rolls, with wear resistance improved by more than 5 times. This effectively reduces energy loss and product surface defects during the rolling process, extending the time between roll replacements. These rolls are widely applied in steel cold rolling, non-ferrous metal rolling, copper foil and aluminum foil production, and other precision rolling fields, especially suitable for extreme working conditions with high loads and small reduction amounts.

Comprehensive Customization Services

We provide full-process customization services from roll design, dimensional tolerances to surface coatings, supporting non-standard dimensions, special roll surfaces, and custom alloy compositions. In processing and material selection, we use compatible tungsten carbide materials, employing different tungsten carbide materials for small-batch and large-batch production according to customer order quantities to achieve optimal cost control.

Proven Industry Applications

Our processing cases across multiple industries demonstrate that customizing processing solutions based on customer-provided operating environments and product requirements can balance both processing accuracy and durability. For processing tolerances, surface roughness, and mating part fitment requirements, we strictly implement process control and inspection procedures to ensure products meet specific industry usage requirements.

Sample Production and Technical Support

Our company can conduct sample production and processing verification according to customers’ specific part drawings and technical requirements. From roll diameter, roll body length, groove design to bore accuracy, all can be customized as needed. We provide subsequent mass production support and technical tracking services. If you need to further discuss your processing requirements, we can provide targeted technical recommendations and customized processing services.

| Product Attributes | |

| Name: Tungsten carbide rolls, | Grade: YG8, K15, YW1, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.003 mm. |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.