Tungsten Carbide Cold-Rolling Rolls | Precision Composite Rolls

Precision tungsten carbide cold-rolling rolls with composite options. Long-lasting, high-performance carbide rolls for demanding applications. Factory direct sales.

- Info

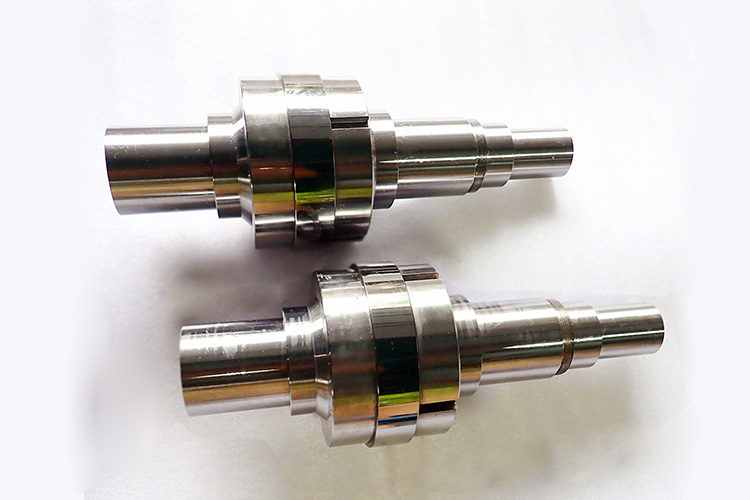

Our company specializes in the sales of precision-machined, composite material, and cold rolling tungsten carbide roll series products, committed to providing high-performance, long-life rolling solutions for the cold rolling industry. In modern rolling industry, the performance of cold rolling mills directly determines the quality of final products and production efficiency. We utilize tungsten carbide materials, achieving optimal material performance balance by selecting different proportions of tungsten carbide materials or choosing different grades of tungsten carbide according to customer requirements.

Advanced Composite Material Design

The composite material rolls adopt a structure of tungsten carbide ring with interference fit to alloy steel core, featuring extremely high hardness and wear resistance, with significantly extended service life. The precision-machined surface roughness can reach below Ra0.2, and for high-requirement products, more refined polishing can be performed to ensure rolled material surface quality. The unique composite material design combines high wear resistance with cost advantages.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Wide Application Range

Our products are widely used in the production of cold-rolled strips including stainless steel, silicon steel, and non-ferrous metals, particularly suitable for finishing mill stands, temper mills, and other positions with extremely high surface quality requirements. Compared to traditional rolls, our products can reduce roll changing frequency to a certain extent and improve equipment utilization rate. The precision-machined surface effectively reduces rolling force, achieving energy saving and consumption reduction. The composite material design reduces costs while ensuring performance.

Comprehensive Customization Services

We provide comprehensive custom processing services, capable of customizing rolls with different specifications, precision grades, and performance characteristics according to customer needs, and provide professional technical consultation and after-sales support to ensure perfect matching between products and production lines.

Why Choose Our Tungsten Carbide Cold Rolling Mills

Choosing our tungsten carbide cold rolling mills means not only selecting high-quality products, but also choosing a professional and reliable partner.

| Product Attributes | |

| Name: Tungsten Carbide Cold-Rolling Rolls, | Grade: K15, YG6N, YW2, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.002 mm. |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.