Tungsten Carbide Formed Drawing Parts | OEM Precision Supplier

Precision tungsten carbide drawing and forming parts for metal-forming dies. High-hardness core components engineered for stamping and wire drawing applications. Custom manufacturing with tight tolerances.

- Info

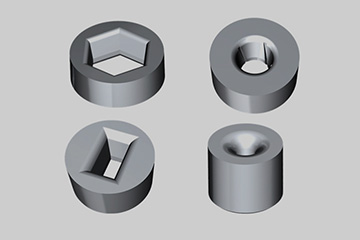

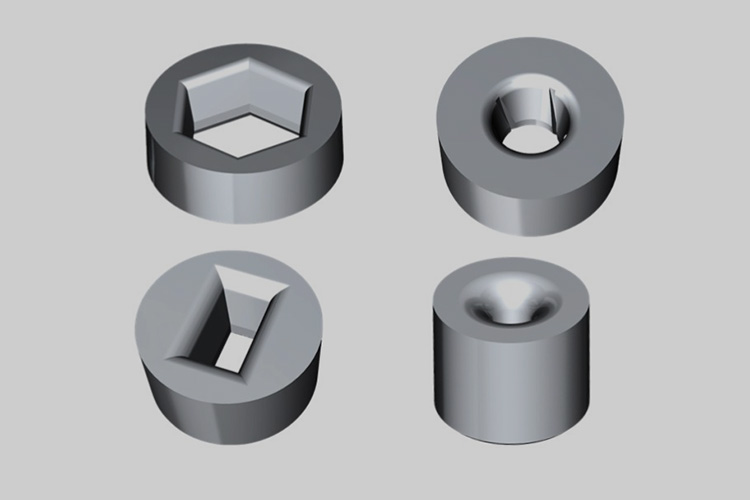

Tungsten Carbide Drawing & Forming Parts

Tungsten carbide drawing/forming parts are precision-processed core components of metal-forming dies made from high-hardness tungsten carbide.

Main Advantages

Their main advantages include extreme wear resistance, excellent anti-galling properties, and superior surface finish, allowing them to maintain stable dimensional accuracy even under high-speed continuous stamping and prevent material sticking.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Primary Applications

They are primarily used in stretch and stamping dies across hardware, electronics, and automotive industries and are particularly suitable for deep drawing and precision stamping of stainless steel, copper alloys, and aluminum alloys.

Benefits Over Alloy Steel Dies

Compared with conventional alloy steel dies, tungsten carbide drawing parts provide several times the wear resistance, which can greatly reduce downtime and die changes, improve production efficiency and part consistency, and lower overall manufacturing costs.

Professional Customization Services

We offer professional customization services and can design and manufacture tungsten carbide drawing cores, inserts, and complete solutions according to product material properties, forming process requirements, and production tempo.

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.

| Product Attributes | |

| Name: Tungsten Carbide Formed Drawing Parts, | Grade: YG8N, K15, YW2, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.001 mm. |