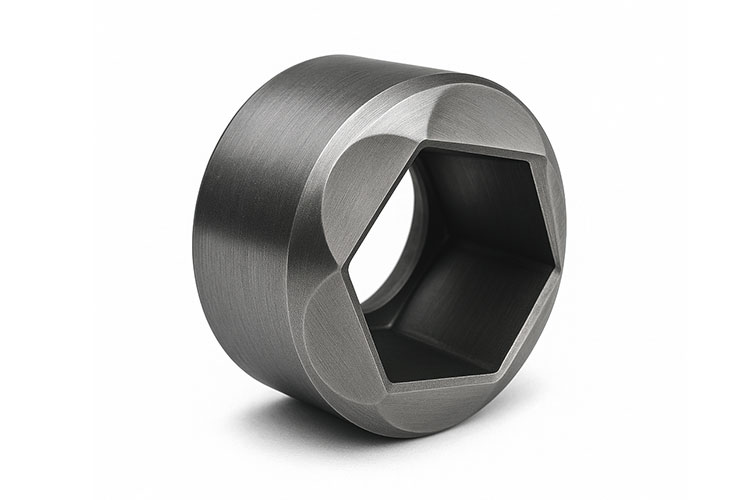

Fine-Grained Tungsten Carbide Solid Trimming Die Set

Fine grain tungsten carbide trimming dies are primarily used for product trimming and deburring processes, serving as essential tools for post-processing of plastic injection molded parts and stamped components. Fine […]

- Info

Fine grain tungsten carbide trimming dies are primarily used for product trimming and deburring processes, serving as essential tools for post-processing of plastic injection molded parts and stamped components. Fine grain cemented carbide dies offer superior wear resistance and more uniform microstructure compared to conventional alloys, capable of withstanding prolonged grinding and impact. Trimming dies manufactured from fine grain tungsten carbide material possess higher hardness and wear resistance, with sharper edges and superior surface precision, delivering smooth and refined trimming results. For ultra-precision component deburring requirements, fine grain tungsten carbide trimming dies can significantly enhance trimming efficiency and consistency.

Leveraging extensive manufacturing experience and advanced equipment, our company provides high-performance custom trimming die services. High-precision machining processes enable die tolerances of ±0.002mm and surface finish of RA 0.05. We design die cavities according to customer product shapes and materials, performing meticulous grinding and polishing treatments to ensure smooth, scratch-free contact surfaces. This ensures trimming dies remain stable and reliable during high-frequency use, withstanding repeated impacts without damage. Tungsten carbide trimming dies achieve exceptional hardness and wear resistance without heat treatment, offering extended product lifespan and reducing equipment changeover and adjustment time.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

We provide customized solutions tailored to specific product requirements. Whether addressing plastic burrs on electronic component housings or warping and burrs on stamped part edges, we deliver tungsten carbide trimming dies that improve trimming quality, reduce secondary processing costs, and enhance product yield rates and production efficiency. By choosing our custom services, clients receive trimming tools with stable performance and extended longevity, thereby improving production efficiency and product quality. Additionally, tungsten carbide dies exhibit excellent thermal stability, adapting to various ambient temperatures, with service life significantly exceeding traditional steel dies. We rigorously inspect cutting edge sharpness and dimensional accuracy throughout the die production process to ensure consistent trimming results. With professional expertise and customization advantages, we provide cost-effective trimming solutions that help enterprises enhance manufacturing quality and overall competitiveness.

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.

| Product Attributes | |

| Name: Fine-grained tungsten carbide solid trimming die set, | Grade: K20, YG8N, YG6X, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.002 mm. |