What Are the 4 Types of Heat Treatment Processes?

Steel processing often requires heat treatment, including annealing, normalizing, quenching, and tempering. However, carbide materials typically do not require heat treatment and may only need stress-relieving treatments. What is heat […]

Steel processing often requires heat treatment, including annealing, normalizing, quenching, and tempering. However, carbide materials typically do not require heat treatment and may only need stress-relieving treatments.

What is heat treatment, and what is its purpose?

Heat treatment is a process of heating, holding at a specific temperature, and cooling solid metals or alloys in a controlled manner to obtain the desired structure and properties. The main purposes of heat treatment are as follows:

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

- To increase hardness, strength, and toughness.

- To improve the wear resistance and corrosion resistance of the surface.

- To enhance processability during machining.

- To eliminate internal stresses generated during processing.

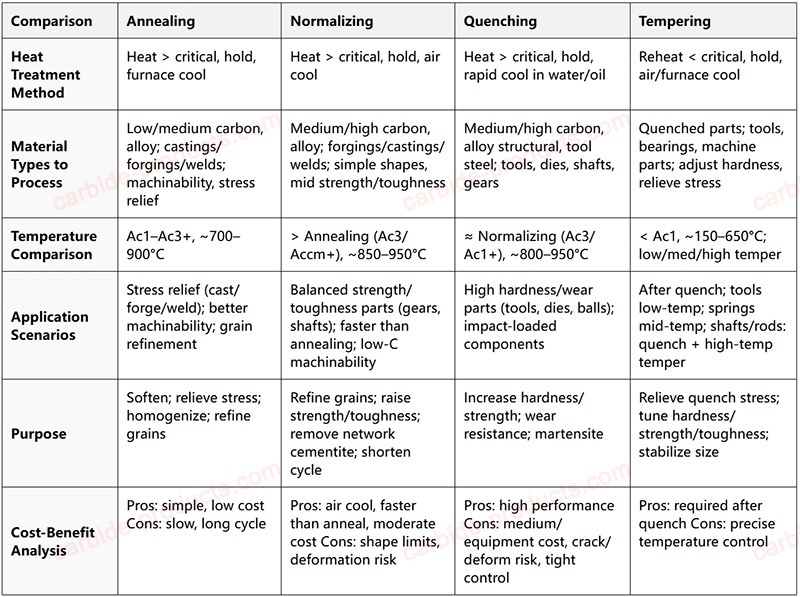

Heat Treatment Processes Comparison Table: Annealing, Normalizing, Quenching, Tempering

| Comparison | Annealing | Normalizing | Quenching | Tempering |

|---|---|---|---|---|

| Heat Treatment Method | Heat to above phase transformation temperature, hold, then cool slowly with furnace | Heat to above phase transformation temperature, hold, then cool naturally in air | Heat to above phase transformation temperature, hold, then cool rapidly in water, oil or other medium | Reheat quenched steel to below phase transformation temperature, hold, then cool slowly (air cool or furnace cool) |

| Material Types to Process | Low/medium carbon steel, alloy steel; castings, forgings, welds; parts requiring improved machinability or stress relief | Medium/high carbon steel, alloy steel; forgings, castings, welds; simply-shaped parts requiring medium strength and toughness | Medium/high carbon steel, alloy structural steel, tool steel; cutting tools, dies, shafts, gears requiring high strength and hardness | Quenched steel parts; parts requiring hardness adjustment and quenching stress relief (tools, bearings, mechanical components) |

| Temperature Comparison | Wide temperature range (Ac1~Ac3 above), moderate-low overall temperature (e.g., carbon steel ~700-900°C) | Temperature slightly higher than annealing (Ac3/Accm above), moderate overall temperature (e.g., carbon steel ~850-950°C) | Temperature close to normalizing (Ac3/Ac1 above), moderate-high overall temperature (e.g., carbon steel ~800-950°C) | Lower temperature (below Ac1, e.g., carbon steel ~150-650°C); classified into low, medium, high temperature tempering based on purpose |

| Application Scenarios | 1. Post-processing of castings/forgings/welds, eliminate processing stress 2. Improve material plasticity for easier machining 3. Refine grain structure for subsequent heat treatment |

1. Mechanical parts requiring balanced strength and toughness (gears, shafts) 2. Replace annealing to simplify process with shorter production cycle 3. Improve machinability of low carbon steel |

1. Parts requiring high hardness and wear resistance (cutting tools, dies, bearing balls) 2. Critical components bearing impact loads in mechanical structures |

1. Post-processing of all quenched steel parts 2. Cutting tools, gauges: low temperature tempering 3. Springs: medium temperature tempering 4. Shafts, connecting rods and other structural parts: quenching + high temperature tempering |

| Purpose | 1. Reduce hardness, soften material for easier machining 2. Eliminate internal stress 3. Uniform organization and composition 4. Refine grain structure for subsequent heat treatment |

1. Refine grain structure, improve organizational uniformity 2. Increase material strength and toughness (superior to annealing) 3. Eliminate network cementite in hypereutectoid steel 4. Simplify process, shorten production cycle |

1. Significantly increase hardness and strength 2. Obtain high wear resistance 3. Obtain martensitic structure |

1. Eliminate quenching stress, reduce brittleness, improve part stability 2. Adjust mechanical properties like hardness, strength, toughness 3. Stabilize part dimensions, prevent deformation |

| Cost-Benefit Analysis | Advantages: Simple process, low equipment requirements (ordinary resistance furnace), low cost Disadvantages: Slow cooling, long production cycle, low efficiency |

Advantages: Simple cooling method (air cool), no special cooling equipment needed, higher efficiency than annealing, moderate cost Disadvantages: Some limitations on part shape (complex parts prone to deformation with air cooling) |

• Equipment and medium costs: Requires quenching medium (water, oil, etc.) and related equipment • Scrap risk: High risk of deformation and cracking, strict control required, may increase cost of correction or scrap • High added value: Key step for achieving high-performance materials |

• Necessary cost: Essential step after quenching, cannot be omitted • Precise control: Temperature control must be precise for stable performance |

What is quenching, and what rules should be followed during quenching?

Quenching is a heat treatment process in which a steel component is heated to a temperature above the Ac3 or Ac point, held at that temperature for a certain time, and then rapidly cooled to obtain martensitic and/or bainitic structures, thereby improving the strength and hardness of the steel component. The following rules should be followed during quenching:

Industrial oven

- The quenching temperature must be maintained. If the temperature is not reached, the component should be further heated and held for a certain time before being placed in the appropriate cooling medium.

- It is preferable to quench at lower temperatures, as this leads to higher hardness and toughness, provided that the desired hardness is achieved.

- Larger carbon steel components are quenched in water, while smaller ones are quenched in oil. When the temperature is between 550-600°C, water quenching is used, and when the temperature is between 200-300°C, oil quenching is employed.

- Tungsten carbide parts are cooled in water, while thin and delicate tools are cooled in oil.

- Long and thin steel components, such as saw blades, should preferably be fixed on an iron plate during quenching to minimize deformation.

What is tempering? What are the different types of tempering, and what are their purposes?

Tungsten carbide oven heating for stress relief

What is tempering? What are the different types of tempering, and what are their purposes?

Although quenching can increase the hardness and strength of steel components, it also introduces internal stresses that can make the steel brittle. Therefore, tempering is necessary after quenching. Tempering involves reheating the hardened steel component to a temperature below the Ac point, holding it at that temperature for a certain time, and then cooling it to room temperature. This heat treatment process aims to relieve internal stresses and improve toughness. Tempering is generally classified into the following three types based on the heating temperature:

- Low-temperature tempering: Heating temperature ranges from 150-250°C. The purpose is to partially relieve internal stresses and increase the toughness of the steel component.

- Medium-temperature tempering: Heating temperature ranges from 350-450°C. The purpose is to further relieve internal stresses and improve the toughness of the steel component.

- High-temperature tempering: Heating temperature ranges from 500-680°C. The purpose is to completely relieve internal stresses and provide the steel component with high hardness, toughness, and wear resistance.

hardness measurement

What is annealing? What is its purpose?

Annealing is a heat treatment process where a metal or alloy is heated to a suitable temperature, held at that temperature for a certain time, and then slowly cooled (usually in a furnace). The purpose of annealing is to reduce hardness, improve machinability, increase ductility, and improve mechanical properties. Additionally, annealing can eliminate internal stresses, uneven microstructures, and coarsening of grains in cast and forged components.

What is normalizing? What is its purpose?

Normalizing is a heat treatment process where steel or steel components are heated above the Ac3 temperature and then cooled in still air. Normalizing differs from annealing in terms of cooling rate; normalizing involves faster cooling, and sometimes the heating temperature is higher than that of annealing. The purpose of normalizing is to refine the structure, increase the strength and toughness of low-carbon and medium-carbon structural steel components, reduce internal stresses, and improve machinability.