Tungsten Carbide Parts for Agricultural Machinery | Manufacturer

Tungsten carbide parts for agricultural machinery offer high hardness and wear resistance through advanced powder metallurgy, providing custom OEM solutions and fast delivery.

- Info

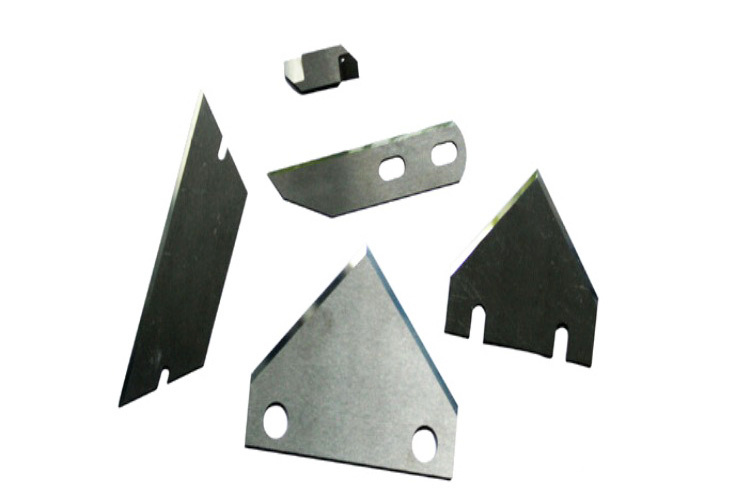

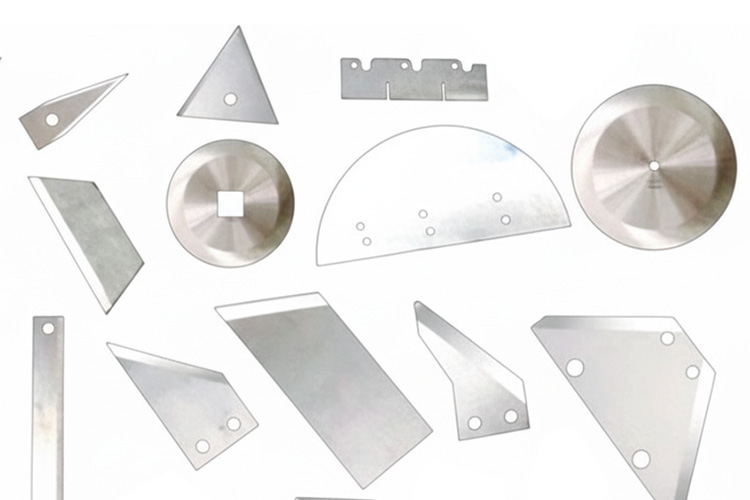

Tungsten Carbide Parts for Agricultural Machinery

Tungsten carbide parts for agricultural machinery are high-performance wear components primarily composed of tungsten carbide and produced by powder metallurgy processes. They offer extremely high hardness and excellent wear resistance.

These parts are mainly used in critical areas of agricultural machines—such as harvester cutting blades, rotary tiller tips, and seeder openers—and can effectively withstand severe abrasion from soil and grit.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Key Advantages

Compared with conventional 65Mn steel parts, tungsten carbide parts can last 5–8 times longer, significantly reducing machine downtime and maintenance time while improving operational efficiency. In complex field conditions, tungsten carbide parts provide outstanding impact resistance and corrosion resistance, adapting to harsh working environments and providing reliable support for modern agricultural mechanization.

Custom Machining Services

We offer professional custom machining services and can tailor tungsten carbide parts of various specifications to match different machine models and operational requirements, helping to comprehensively improve agricultural production efficiency.

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.

| Product Attributes | |

| Name: Tungsten Carbide Parts for Agricultural Machinery, | Grade: YG8, K15, YW1, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.003 mm. |