Tungsten Carbide Parts for Metal Can Molds | Custom Factory

Tungsten carbide parts for metal can molds deliver high wear resistance and stable performance, supporting custom OEM production with durable inserts and fast delivery.

- Info

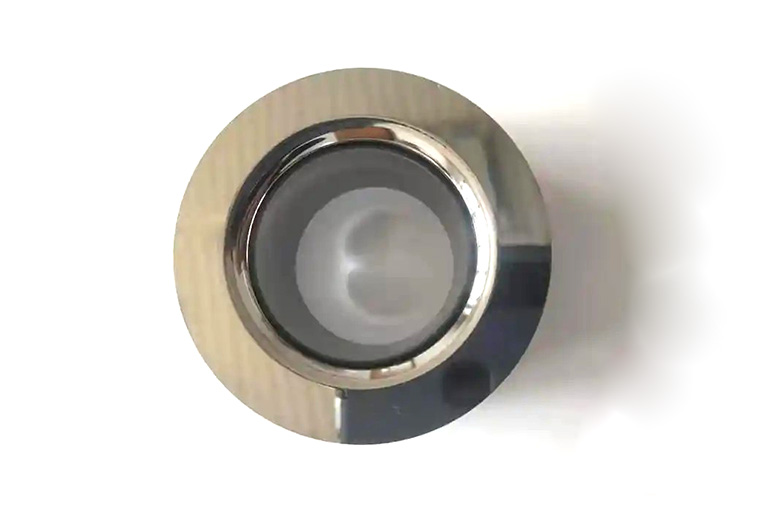

Metal Can Molds with Tungsten Carbide Inserts

Metal can molds are specialized tooling used to produce cans for food, beverages, chemicals, and other metal packaging. The mold body is typically made from high-quality alloy tool steel with tungsten carbide wear inserts in critical areas, manufactured through precision machining and heat treatment to ensure stable, long-term production.

Key Features

Key features include high dimensional accuracy, excellent wear resistance, and stable service life; mold surfaces undergo special treatments to achieve very low friction coefficients and support high-speed continuous production with consistent can forming quality.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Industrial Applications

These molds are used in metal packaging industries for body drawing, flanging, necking, and seaming operations and are suitable for tinplate and aluminum materials.

Advantages of Tungsten Carbide Enhancement

Compared with ordinary molds, tungsten carbide-enhanced metal can molds have significantly longer service life, greatly reducing downtime and maintenance while improving production efficiency and lowering can production costs.

Full-Service Customization

We provide full-service customization and can design and manufacture complete mold solutions according to can specifications, production speed, and material properties.

| Product Attributes | |

| Name: Tungsten Carbide Parts for Metal Can Molds, | Grade: YG6N, K20, YW2, |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 10-20 mesh |

| Machining: Grinding, | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.002 mm. |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.