-

-

Cutting or Grinding in Carbide Machining: Choose the Right Method

Discover when to use cutting vs. grinding for tungsten-carbide parts — factors like shape, hardness, speed, surface finish and residual stress influence the choice. Read on to optimize carbide machining.

More

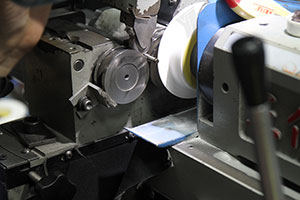

grinding machining

Carbide grinding machining. OD, ID, centerless, profile grinding, and surface grinding on carbide. 1 pcs production. Tolerance 0.001mm.

-

-

Carbide Profile Grinding Services | Custom PG Grinding ±0.001mm

Expert custom profile grinding carbide services. Carbide tip grinding & punch die manufacturing with ±0.001mm accuracy. High-quality PG grinding in China.

More

-

-

Diamond Wheels for Grinding Carbide | Silicon Carbide Wheels

Premium diamond wheels for grinding carbide materials. Synthetic diamond & green silicon carbide cutting wheels for optimal machining.

More

-

-

Grind Tungsten Carbide: Machines, Wheels & Grinding Fluid

Discover the essential techniques for machining tungsten carbide: choosing the right grinder, using diamond wheels, proper coolant and expert technique for high-precision parts.

More

-

-

What Grinding Wheel for Tungsten Carbide?

To grind tungsten carbide, it is preferable to use a diamond grinding wheel, followed by a CBN grinding wheel, and a green silicon carbide grinding wheel. Tungsten carbide is widely […]

More

-

Send Email

-

Request a Quote

-

WhatsApp

-

Share

-

Back to top