Alloy Steel Mold Materials: Manufacturing Process

Learn how alloy steel for mold making is produced, from raw materials and melting to heat treatment and testing. Improved performance, stability, and precision for tooling.

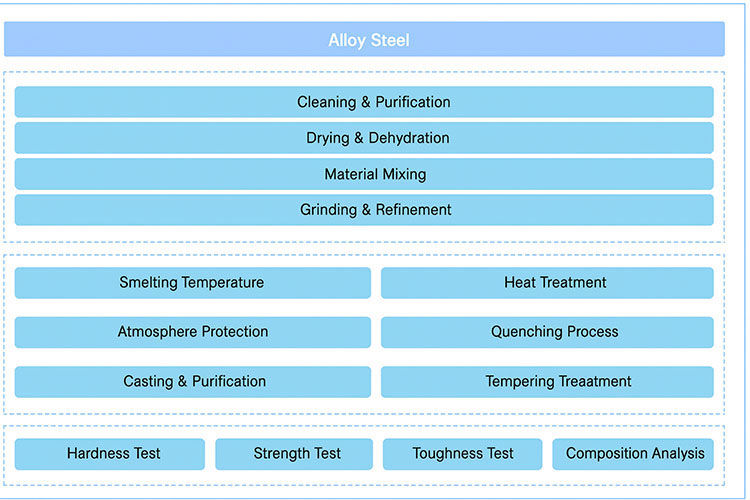

The production of alloy steel is a complex process that involves everything from raw material preparation and pre-treatment to melting operations and performance testing. Each stage is further divided into multiple steps. Proper preparation and pre-treatment of the raw materials lay the foundation for the alloy’s final properties. Through precise proportioning and thorough cleaning, impurities are minimized. During melting and casting, strict control over melting parameters and close monitoring of molten metal flow and solidification are required to ensure dense and uniform castings. Heat treatment and machining further refine the alloy’s microstructure and enhance its mechanical properties. Quality inspection and performance testing rely on advanced analytical methods to evaluate chemical composition, physical characteristics, and microstructure, ensuring every batch meets high industry standards.

Raw Material Selection and Proportioning

In alloy steel production, selecting raw materials and determining accurate proportions are fundamental steps. Core materials include high-purity iron, carbon, and appropriate alloying elements. Depending on the steel grade, elements such as chromium, molybdenum, vanadium, nickel, manganese, and silicon may also be required. Common alloy steels used in the mold manufacturing industry include 45 steel, 40Cr alloy steel, Cr12MoV, DC53, 8503 mold steel, and 35CrMo alloy steel. These materials must strictly comply with industry standards, be sourced from reliable suppliers, and undergo rigorous inspection to ensure low impurity levels and consistent composition to meet specific performance requirements.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

During the proportioning stage, engineers calculate and mix the precise ratios of each component based on the desired performance, application conditions, and manufacturing requirements. For example, carbon and chromium may be increased to enhance hardness and wear resistance, while other alloying elements are adjusted to improve toughness and machinability. The interactions between elements must also be considered, as they can significantly influence the alloy’s overall behavior.

Raw Material Cleaning and Drying

Before mixing, all raw materials must undergo thorough cleaning and drying. This step removes oils, oxides, and other contaminants that could compromise final product quality. Ultrasonic cleaning combined with chemical cleaning is commonly used. Ultrasonic vibration knocks off stubborn surface contaminants, while chemical cleaning uses specialized solvents and catalysts to dissolve residues under controlled temperature and pressure.

After cleaning, drying is necessary to prevent moisture from creating porosity or inclusions during melting. Hot-air or vacuum drying is typically used, with strict control over temperature and duration to eliminate moisture while avoiding oxidation or particle agglomeration. Properly prepared raw materials ensure stable alloy quality throughout the production process.

Alloy Steel Production Diagram

Alloy Melting and Casting

Melting is a critical stage in alloy steel production. Before melting begins, melting parameters must be carefully established based on material characteristics, chemical composition, and equipment capabilities. Temperature control is essential: the melting temperature must be sufficiently high to fully liquefy all components and ensure uniform mixing. Proper temperature reduces gas porosity and inclusions, improving overall quality.

Atmosphere control is equally important. Oxidation and nitriding can degrade alloy performance, so furnace gas composition and pressure must be precisely regulated. Melting time must also be optimized. Insufficient melting time results in incomplete dissolution or uneven mixing, while excessive time may cause grain coarsening and negatively affect mechanical properties.

Process Control During Melting

To maintain uniformity and consistent temperature during melting, continuous stirring and monitoring are required. These operations promote efficient melting, homogenization, and temperature stability throughout the molten alloy.

Casting and Cooling

Once melting is complete, the alloy is cast into pre-prepared molds. These molds must have high-temperature resistance, dimensional accuracy, good thermal conductivity, and appropriate thermal expansion characteristics to ensure controlled heat transfer and cooling rates. Common mold materials include sand, metal, and ceramic. Both casting speed and cooling rate must be carefully managed to prevent defects and achieve uniform solidification.

Heat Treatment and Machining

Heat treatment is essential for improving alloy steel microstructure and performance. Depending on the application, processes such as quenching, tempering, and annealing may be selected to achieve the desired mechanical properties.

Quality Inspection and Performance Testing

Chemical Composition Analysis

Chemical composition analysis is foundational to alloy steel quality control. Major alloying elements such as carbon, chromium, molybdenum, and vanadium must be precisely measured, and impurity elements such as sulfur and phosphorus must be strictly monitored.

Physical Property Testing

Physical property testing evaluates the mechanical performance of alloy steel. Common tests include hardness, tensile strength, yield strength, impact toughness, fatigue strength, and friction coefficient.

Microstructural Examination

Microstructural analysis helps reveal the internal structure of alloy steel. By observing grain morphology, grain size, phase distribution, and microstructural composition, engineers gain insight into how processing conditions influence material properties and performance.

Connect with us