Tungsten Carbide Insert Powder Metallurgy Die & Pressing Tooling

Tungsten carbide insert die & pressing tooling manufacturer. Custom PM dies, punch tooling & molds for precision metal forming. Get free quotes from China suppliers.

- Info

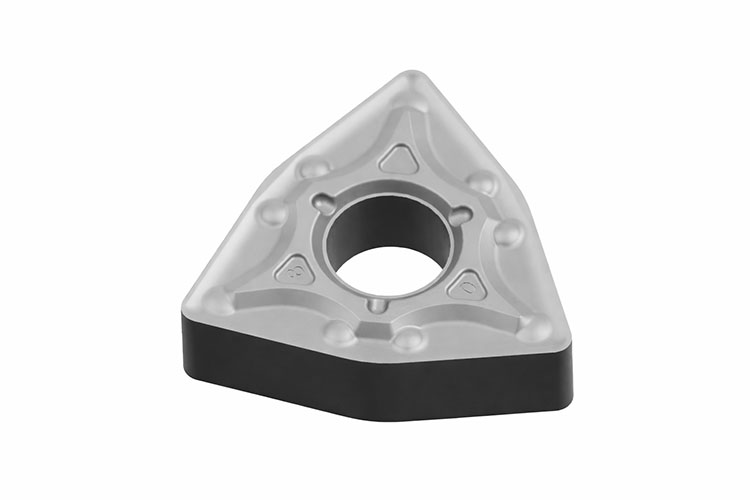

Tungsten carbide inserts have become a powerful tool in cutting operations due to their high hardness and excellent wear resistance, and their production relies on professional powder metallurgy die. Our company specializes in this field, providing customized machining services and core forming equipment for efficient mass production of various tungsten carbide inserts including turning inserts, milling inserts, and drill bit inserts.

Our dies and pressing tooling are specifically designed for high-volume, high-precision production of carbide inserts, compatible with WC-Co, WC-TiC-Co and other cemented carbide powders. They serve a wide range of industrial sectors including mechanical manufacturing, CNC machining, woodworking, and metal cutting, serving as fundamental and critical tools for producing high-quality cutting tools.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Design and Machining of Tungsten Carbide Insert Powder Metallurgy Die & Pressing Tooling

Tungsten carbide insert pressing dies typically feature precision multi-stage buffer structures and quick-change die systems. Core components include upper punch, precision cavity die, lower punch plate, and multi-stage buffer ejection mechanisms. The die’s core components are machined by experienced engineers with tolerances up to ±0.002mm and surface finish polish up to RA0.05. Critical core components are manufactured from high-performance tungsten carbide, a material produced through powder metallurgy processes using refractory metal carbides and metal binders, achieving HRA hardness of 86 to 93, equivalent to 69 to 81 HRC. Additionally, it exhibits excellent heat resistance, maintaining hardness virtually unchanged at 500°C and retaining high hardness even at 1000°C, making it ideally suited for long-duration, high-load powder pressing operations.

Through optimized process design and high-performance die materials, a single set of dies can stably produce over 400,000 pieces, tripling the service life compared to conventional dies, with finished insert qualification rates exceeding 99%. Precision guide mechanisms and buffer systems ensure stable and reliable pressing processes, guaranteeing uniform density distribution and precise geometric dimensions in the pressed insert blanks.

For quotations or process evaluations, please provide product drawings, material requirements, and expected production volumes. Our application engineers will provide professional machining solutions and customized quotations based on your information, ensuring optimal balance between product performance and cost.

| Product Attributes | |

| Name: Tungsten carbide insert powder metallurgy die & pressing tooling | Origin: China |

| Material: Tungsten carbide, Powder tool steel, HSS; As required | Lead time: 15–30 days |

| Main machining equipment: Grinding, EDM, WEDM, CNC, PG | Customizable: Yes |

| Process type: Powder metallurgy pressing mold | Polishing: Ra 1.6 – Ra 0.05 |

| Surface treatment, Heat treatment | Precision: 0.001 mm |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.