-

-

Micro EDM Process: Precision Electric Discharge Machining Guide

Learn micro EDM machining principles, applications, and techniques. Guide to micro electric discharge machining for precision engineering.

More

Carbide Wire EDM

Low-priced China company buy custom oil cutting slow wire, water cutting slow wire. Sodick slow wire machining service. Wire-EDM machining.

-

-

Wire EDM Carbide: Can You Machine Tungsten Carbide with EDM?

Yes, wire EDM can machine carbide effectively. Learn how electrical discharge machining cuts carbide materials, working principles and key precautions.

More

-

-

What Is EDM Wire Made Of? Materials & Types Explained

Learn the main EDM wire materials—copper, molybdenum, alloys, and more. Understand how each type affects cutting performance.

More

-

-

Wire EDM Hole Drilling: Precision Methods, Advantages & Limitations

Yes, wire EDM can drill holes with precision. Learn the wire EDM drilling process flow for tungsten carbide, HSS, and mold steel, along with their advantages and disadvantages.

More

-

-

Wire Cut EDM vs EDM: Key Differences & Machine Types Explained

Discover the difference between wire cut EDM and EDM machines. Learn about wire cutting, through holes, blind holes, and which EDM type suits your needs.

More

-

-

Wire EDM Surface Finish – Electrical discharge machining Roughness Chart & Guide

Surface finish in electrical discharge machining (EDM): Oil cutting can achieve Ra 0.2 μm, water cutting can achieve Ra 0.4 μm, and EDM surface finish usually ranges between Ra 0.2-0.3μm, and a complete roughness chart to guide your machining decisions.

More

-

-

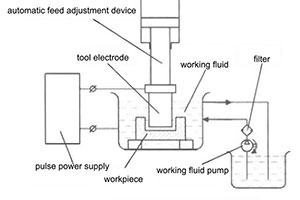

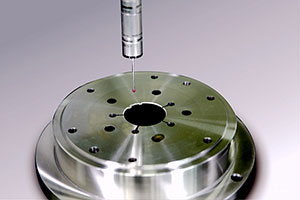

What Is Micro EDM? Processes, Characteristics & Applications

Learn the characteristics, applications, and processes of Micro EDM. Include Micro EDM Forming, Wire Electrical Discharge Grinding, Micro Wire EDM Cutting.

More

-

-

Improving Wire EDM Surface Finish | Techniques & Materials

Discover practical ways to enhance wire EDM surface smoothness and the role material composition plays in finish quality.

More

-

-

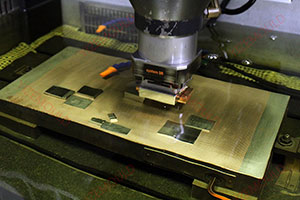

What Is EDM Wire Cutting? Overview, Characteristics & Trends

Discover wire EDM cutting technology for complex precision parts. Understand the process, Key Characteristics, and industrial applications Trends.

More

-

Send Email

-

Request a Quote

-

WhatsApp

-

Share

-

Back to top