Square Tools Manufactured by Tool Steel Powder Metallurgy

Square tool steel powder metallurgy tooling is specifically designed for producing high-precision, densely structured square tool steel components. As a professional powder metallurgy tooling manufacturer, we provide custom machining services, […]

- Info

Square tool steel powder metallurgy tooling is specifically designed for producing high-precision, densely structured square tool steel components. As a professional powder metallurgy tooling manufacturer, we provide custom machining services, offering high-precision forming solutions for square pads, square sleeves, square structural parts, and other products in mechanical parts, hardware tools, automotive components, and related industries.

Our tooling is widely used in the research and manufacturing of tool steel products, powder metallurgy, superconducting materials, batteries, rare earth materials, advanced ceramics, and other new materials. Through advanced powder metallurgy processes, we achieve one-step precision forming of square tool steel parts, effectively reducing subsequent machining operations, significantly lowering manufacturing costs, and ensuring dimensional consistency and stability of products.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Powder Metallurgy Tooling Design and Machining Services

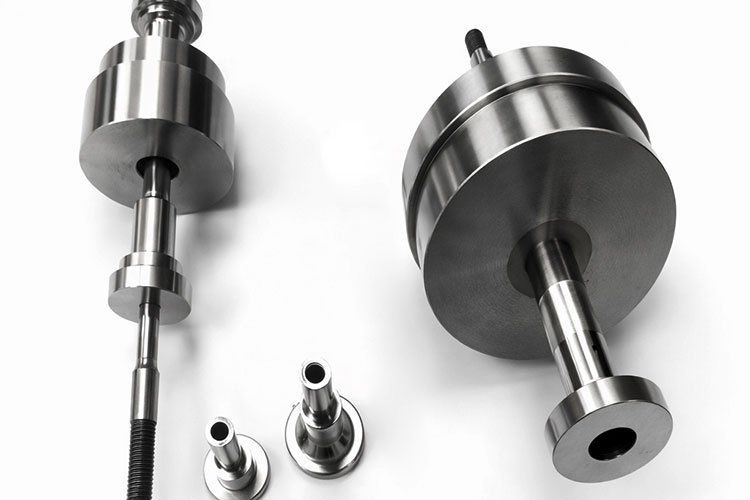

To address the challenges of stress concentration at corners and edges during demolding of square compacts, which can easily lead to internal cracks, our tooling adopts a composite structural design. Core components include the female die, upper punch, lower punch plate, outer die sleeve, and limiting sleeve. The advanced split-type female die design consists of four supporting plates assembled end-to-end, combined with a tapered outer die sleeve that is smaller at the top and larger at the bottom. During demolding, the female die and compact are pressed out together, avoiding direct application of enormous demolding resistance to the compact. This perfectly solves the demolding difficulties and internal crack defects caused by the lack of draft angles in square compacts. Core components are machined by skilled engineers with tolerances achievable to ±0.002mm.

Tooling Material Selection

Our tooling materials are preferentially made from SKD11 tool steel and powder metallurgy tooling steel, strengthened through vacuum hardening, deep cryogenic treatment, and precision grinding processes, achieving hardness of HRC58 to 62 with excellent compression resistance and wear resistance. Cavities are machined from integral forged blanks, ensuring sufficient die body rigidity. Dimensional tolerances are controlled within ±0.002mm, with squareness deviation less than or equal to 0.005mm, ensuring neat corners and uniform dimensions of finished products. Die surfaces are treated with mirror polishing and TiN coating to reduce powder adhesion and improve demolding smoothness. For powder compaction environments requiring high longevity and high-temperature resistance, tungsten carbide material is used to achieve extended service life.

For quotations or process evaluations, please provide product drawings, material requirements, and expected production volume. Our engineering team will provide professional machining solutions and customized quotations based on your information, ensuring optimal balance between product performance and cost.

| Product Attributes | |

| Name: Square tool steel powder metallurgy tools | Origin: China |

| Material: Tungsten carbide, Powder tool steel, HSS; As required | Lead time: 15–30 days |

| Main machining equipment: Grinding, EDM, WEDM, CNC, PG | Customizable: Yes |

| Process type: Powder metallurgy pressing mold | Polishing: Ra 1.6 – Ra 0.05 |

| Surface treatment, Heat treatment | Precision: 0.001 mm |

Please feel free to consult with us for customization. We will provide professional advice and a quotation plan based on your specific needs.